scp - Step-Cycle-Pro

hintergrund bild

Pro’s

- no cycle time increase

- improves efficiency

- enhances tool life

- less intervention facile

- more profit

Innovation in chip management

- a new air-cut Technology to manage the requirements of hard-to-machine materials

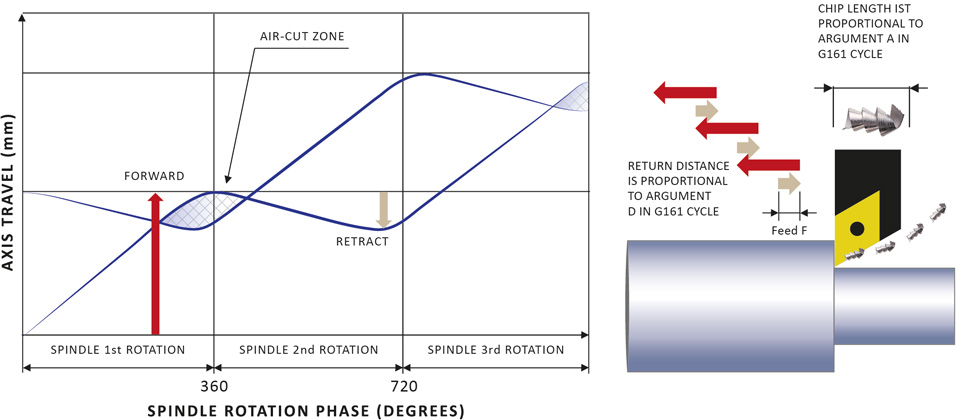

The STEP CYCLE PRO (SCP) system delivers its highly effective ‘air-cut’ chip-breaking operation by oscillating the axis in synchronisation with the spindle rotation cycle and can be used simultaneously on both the main- and sub-spindles. This new cutting method increases production efficiency by eliminating machine stoppages related to swarf entanglement and enhances tool life by reducing the temperature of the tip whilst in operation. Developed to suit a variety of machining types including turning, drilling, facing and grooving, SCP offers a dedicated interface on the FANUC CNC-system.

That allows engineers to set the ideal program conditions and chip length. The SCP command is easy to insert into your NC program, as the control automatically calculates the recommended coefficients A for the chip length and the oscillation value D based on the specified speed and feed rate. All new machines are mechanically equipped to withstand the increased load associated with oscillation cutting. This enables customers to trial the function in ‘setting mode’ before they purchase the option on a permanent basis.

video

grafik air-cut