Advantages & Features

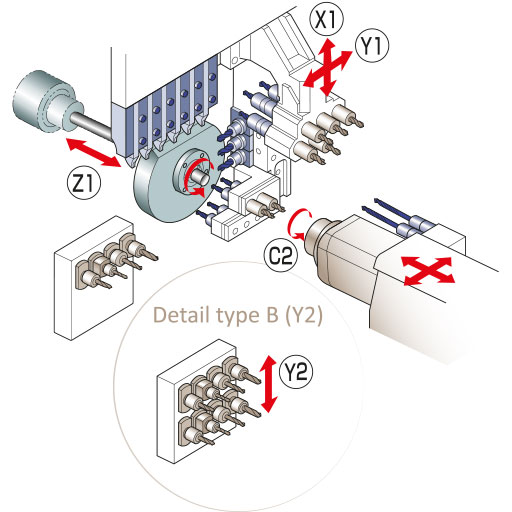

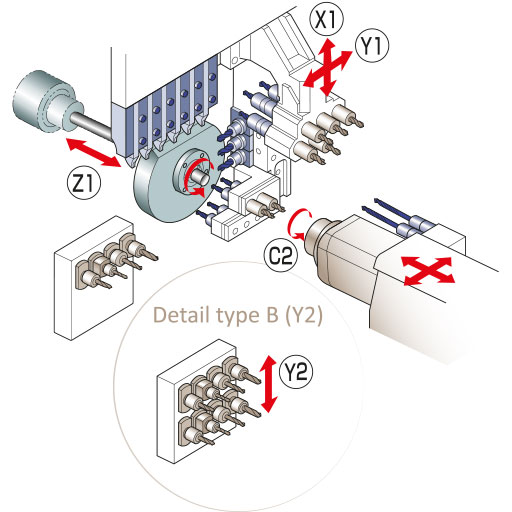

The SR-20JII automatic lathe with or without guide bush (Hybrid) is very stable, powerful and flexible.

Especially to emphazise is type-B, equipped with a Y2 axis for counter-operational machining. With this axis, the recovery station has 8 tool positions (fixed or driven).

Technical details

| CNC control System | FANUC 32i-B |

| Number of axes (total) | 7 (type A) / 8 (type B) |

| Capacity coolant tank | 202 liter |

| Dimensions (WxBxH) | 2250 x 1200 x 1700mm |

| Power consumption | 4.8kVA |

| Weight | 2750kg |

| Rapid feed rate | 35m/min (all, except C-axis) |

Kinematics SR-20JII type A / B

Front Site

| Number of axes | A:4 / B:4 |

|---|---|

| Main spindle (headstock) | Z1 / C1 Axe |

| Tool post | X1 / Y1 Axe |

| max. Machining diameter | 20mm / 23mm option |

| max. Headstock stroke (sliding/fixed headstock) |

205mm / 50mm |

| max. Drive power | 2.2kW / 3.7kW |

| max. Main spindle speed | 10'000 1/min |

Tools Gang tool post |

|

| Turning tools front | 6 □12mm |

| Drilling tools | 5 (ER16) |

| Cross working tools | 5 (ER16) |

| max. Speed | 8'000rpm |

Tools Deep drilling / Milling Unit |

|

| Number of tools | 2 |

Back Side

| Number of axes | A: 3 / B: 4 | |

|---|---|---|

| Sub Spindle | X2 / Z2 / C2 axis | |

| Axis vertical backworking | Y2 (Type B) | |

| max. Gripping diameter | 20mm / 23mm option | |

| max. Sub spindle speed | 10'000rpm | |

| max. Drive power | 2.2kW / 3.0kW | |

Backworking Tools |

||

| Tool stations | A:4 (fix or driven) B:8 (fix or driven) | |

| max. Sub spindle speed | 8'000rpm | |