Advantages & Features

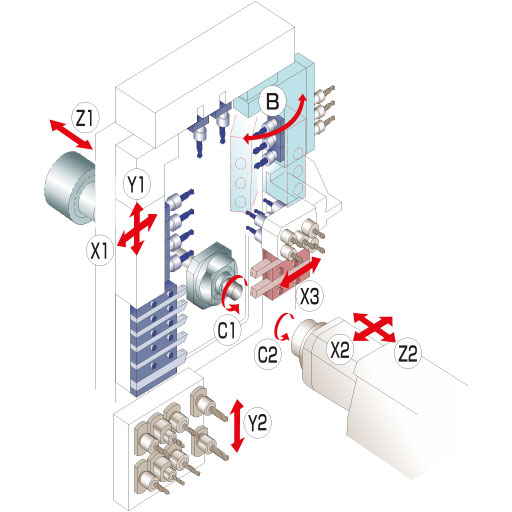

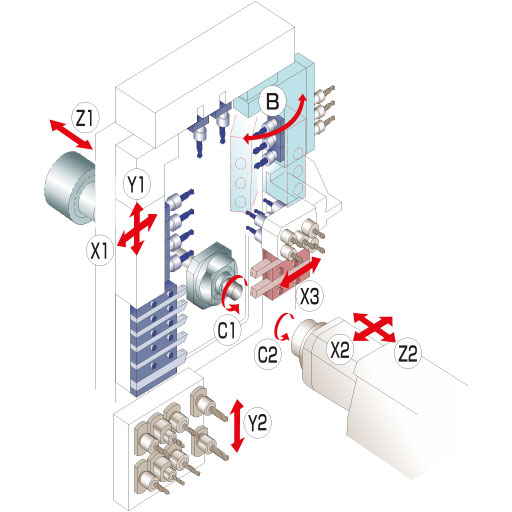

The SR-38 convertible automatic lathe with or without guide bush (Hybrid) has a material passage of 38 mm. Since two turning tools can be used at the same time (X1 and X3), roughing and finishing can be carried out in one pass. With the controlled B-axis, machining is possible at any angle.

The back processing is completely independent (Y2 axis).

Technical details

| CNC control system | FANUC 31i-B5 plus |

| Number of axes (total) | 10 |

| Capacity coolant tank | 359 liter |

| Dimensions (LxWxH) | 3192 x 1315 x 2120mm |

| Weight | 4300kg |

| Power consumption | 16.9kVA |

| Rapid feed rate | 36m/min (X1, Y1, Z1, X2, Z2) |

Kinematics SR-38 type B

Front Side

| Number of axes | 6 |

|---|---|

| Main spindle (Headstock stroke) | Z1 / C1 axis |

| Tool post | X1 / X3 / Y1 / B-axis |

| max. Machining diameter | 38mm / 42mm Option |

| max. Headstock stroke (sliding/fixed headstock) | 320mm / 95mm |

| max. Drive power Main spindle | 7.5kW / 11kW |

| max. Speed Main spindle | 7'000 rpm |

Tools Gang tool post |

|

| Turning tools front | 4x (□ 16mm) / 1x (□ 20mm) |

| Turning tools on X3-Slide | 2x (□ 16mm) |

| Drilling tools (5-spindle sleeve holder) | 3x (ER16) / 2x (ER20) |

| Cross working tools | 6x ER16 |

| B-Axis | 3x (ER16) Main side 3x (ER16) Back side |

| Cross working speed | 6'000 rpm |

| max. cross machining drive power | 2.2kW / 3.0kW |