Advantages & Features

The ST-38 is designed for the production of complex components and has a bar passage of 38mm. With three revolvers at 10 tool stations each (fixed or driven), diverse modular holders can be installed. The lower revolver also allows simultaneous processing of the main and counter spindles, which reduces the cycle time significantly.

Technical details

| CNC control system | FANUC 31i-B5 |

| Number of axes (total) | 12 |

| Capacity coolant tank | 245 liter |

| Dimensions (LxWxH) | 3477 x 1859 x 1865mm |

| Weight | 6250kg |

| Power consumption | 10.5kVA |

| Rapid feed rate | 30m/min (X1, X2, X3, Z1, Z2, Z3) |

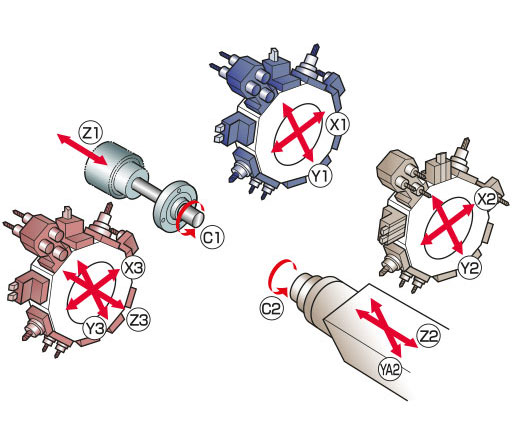

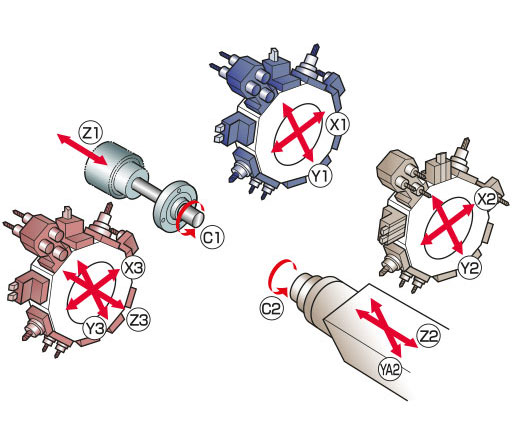

Kinematics ST-38

Front Side

| Number of axes | 7 |

|---|---|

| Main spindle (Headstock stroke) | C1 / Z1 axis |

| Turret 1 | X1 / Y1 axis |

| Turret 3 | X3 / Y3 / Z3 axis |

| max. Machining diameter | 38mm |

| max. Headstock stroke standard | 350mm |

| max. Main spindle speed | 7.000 rpm |

| Main spindle drive power | 7.5kW / 11.0kW |

Tools sleeve holder |

|

| Number of tools | max. 3 per station |

| max. Drilling capacity | Ø 23mm |

| max. Tapping capacity | M16 x P2.0 |

Driven tools |

|

| Number of tools | max. 2 per station |

| max. Drilling capacity | Ø 10mm |

| max. Tapping capacity | M8 x P1.25 |

| max. Speed | 5'750 rpm |

Back Side

| Number of axes | 5 | |

|---|---|---|

| Sub Spindle | C2 / YA2 / Z2 axis | |

| Turret 2 | X2 / Y2 axis | |

| max. Gripping diameter | 38mm | |

| max. Sub spindle speed | 7.000 rpm | |

| Sub spindle drive power | 5.5kW / 7.5kW | |

Backworking tools |

||

| Number of tools | max. 3 per station | |

| max. Drilling capacity | Ø 23mm | |

| max. Tapping capacity | M12 x P1.75 | |

Driven tools |

||

| Number of tools | max. 2 per station | |

| max. Drilling capacity | Ø 10mm | |

| max. Tapping capacity | M8 x P1.25 | |

| max. Speed | 5'700 rpm | |