Advantages & Features

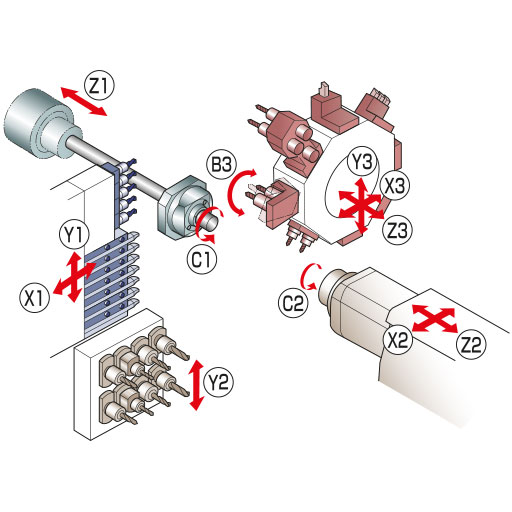

The SV-20R automatic lathe, with or without guide bush (Hybrid), is the further development of the successful SV series. An 8-speed revolver with integrated B-axis was added. With the X2 axis it is possible to work at the back in an out-of-the-middle position. With the Y2 axis, 8 additional tool stations (fixed or powered) are available.

Technical details

| CNC control system | FANUC 31i-B5 |

| Number of axes (total) | 12 |

| Capacity coolant tank | 220 liter |

| Dimensions (WxDxH) | 2730 x 1350 x 1865mm |

| Weight | 4150kg |

| Power consumption | 6.3kVA |

| Rapid feed rate | 30m/min (X1, X2, X3, Y1, Z1, Z2, Z3) |

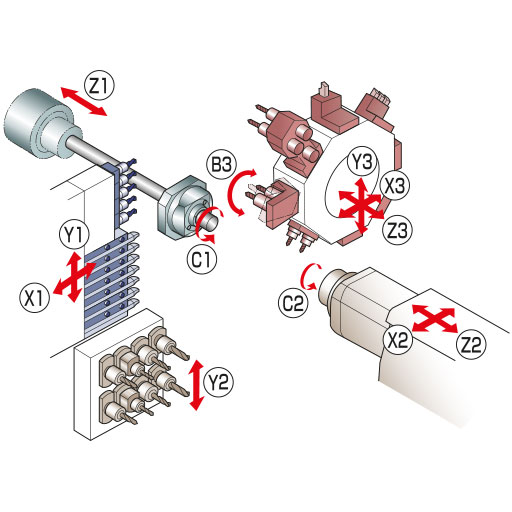

Kinematics SV-20R

Front Side

| Number of axes | 8 |

|---|---|

| Main spindle (Headstock stroke) | C1 / Z1 axis |

| Tool post | X1 / Y1 axis |

| max. Machining diameter | 20mm / 23mm option |

| Rotating sledges | X3 / Y3 / Z3 / B3 |

| Headstock stroke (sliding/fixed headstock) |

205mm /55mm |

| max. Speed | 10'000 rpm |

| Drive power | 3.7kW / 5.5kW |

Tools Gang tool post |

|

| Number of tools | 7 (□ 12 mm) |

| Powered tools | 5 (ER16) |

| max. Speed | 8'000 rpm |

Turret tools |

|

| Number of stations | 8 (4 with B-Axis function) |

| Stationary tools | max. 3 per station |

| Driven tools | max. 2 per station |

| max. Speed | 5'750 rpm |