Advantages & Features

The SX-38 automatic lathe, with or without guide bush (Hybrid), convinces with excellent stability. The swallow tail guide on various axes as well as the hydraulic clamping device on the B-axis guarantee high-performance machining. The revolver is equipped with 10 tool stations and can be used for highly complex components.

The Y2 axis completes the overall package.

Technical details

| CNC control system | FANUC 31i-B5 |

| Number of axes (total) | 12 |

| Capacity coolant tank | 375 liter |

| Dimensions (WxDxH) | 2955 x 1430 x 1975mm |

| Weight | 5'800kg |

| Power consumption | 9.5kVA |

| Rapid feed rate | 30m/min (X1, X2, X3, Y1, Z1, Z2, Z3) |

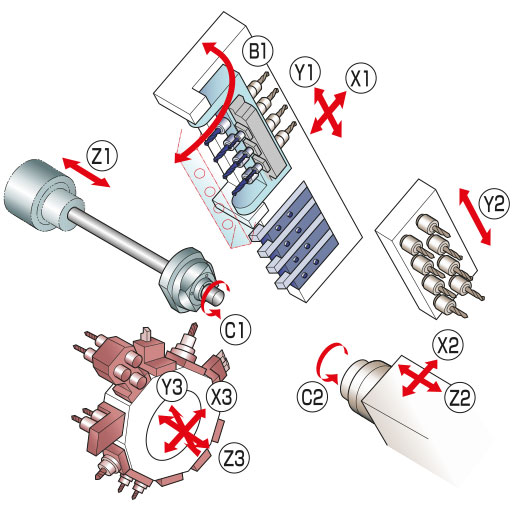

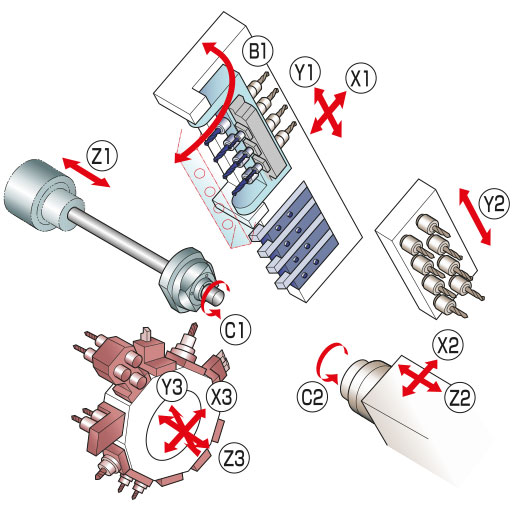

Kinematics SX-38

Front side

| Number of axes | 8 |

|---|---|

| Main spindle | C1 / Z1 axis |

| Tool post | B1 / X1 / Y1 axis |

| Turret | X3 / Y3 / Z3 axis |

| max. Machining diameter | 38mm / 42mm option |

| max. Headstock stroke (sliding / fixed headstock) |

320mm / 95mm |

| max. Main spindle speed | 7'000 rpm |

| max. Drive power | 7.5kW / 11.0kW |

Tools Gang tool post |

|

| Turning tools | 3 (□16mm) 1 (□20mm) |

| Cross working tools B axis | 4 (ER20) Front side 4 (ER16) Back side |

| max. Speed cross working | 6'000 rpm |

Tools turret |

|

| Number of stations | 10 |

| driven tools | max. 2 per station |

| stationary tools | max. 3 per station |

| max. Speed cross working | 5'700 rpm |