Advantages & Features

The SD-26 has been developed to capable of up to 26-dia. machining. It is mainly targeted at complex-shaped parts for automotive, hydraulic/pneumatic equipment and medical-related uses.

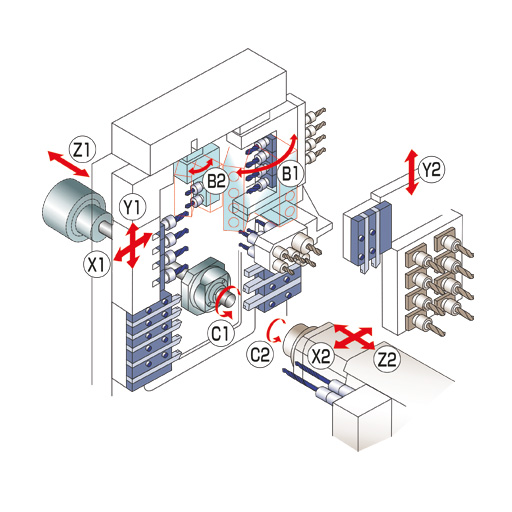

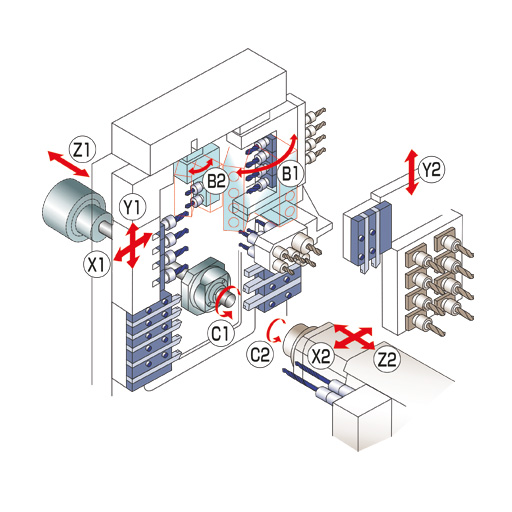

Equipped with a 4-spindle facing-type milling unit with a tool swivel control axis (B1-axis) capable of programmable simultaneous 5-axes control. Additional a B2-axe for positionable use.

Technical details

| CNC control system | FANUC 31i-B5 Plus |

| Number of axes (total) | FANUC 31i-B5 Plus |

| Number of axes (total) | 10 |

| Capacity coolant tank | 228 liter |

| Dimensions (LxDxH) | 2550 x 1300 x 2000 mm |

| Weight | 3600 kg |

| Power consumption | 11.98 kVA |

| Rapid feed rate | 36 m/min (all axes, except C+B axis) |

Kinematics SD-26 type S

Front Side

| Number of axes | 6 |

|---|---|

| Main spindle | C1 / Z1 axis |

| Tool Post | X1 / Y1 / B1 / B2-axis (independent programmable) |

| max. Machining diameter | 26mm |

| Headstock stroke (sliding/fixed headstock) |

260mm / 65mm |

| max. Speed | 10'000rpm |

| max. Drive power | 5.5kW (7.5kW) |

Tools Gang tool post |

|

| Turning tools | 5+2 (□16 mm) |

| Drilling tools | 5 (4x [ER16], 1x [ER20]) |

| Cross working tools | 4 (variable) |

| B1-axis driven | 4 front / 4 back |

| B2-axis driven | 2 (variable) |

| max. Speed | 8.000rpm |

Tools Deep-hole drill unit |

|

| Number of tools | 2 |